Our workshop has been specifically set up to provide fast high quality services for the marine, offshore and shore-based industry. This is ideal for carrying out custom part fabrication to your drawings, repairs, or part renewal.

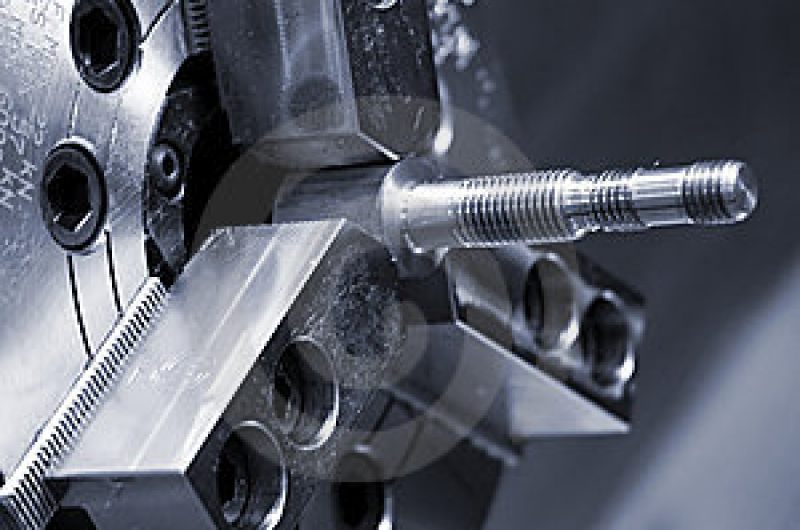

The shop is equipped with vertical and horizontal boring machines, lathes, milling machines, drill presses, grinders and key cutters. These machines, in combination with our welding equipment enable HSR to carry out reconditioning of most all major engine and machinery components.

DNV-GL quality procedures require each job to be planned on check sheets to ensure conformity. Jobs in progress are inspected and signed off at each stage, and subject to a thorough final inspection before release to customers.

All precision and test equipment is calibrated in accordance with DNV-GL Quality manual requirements.